5

STANDARDCONFIGURATION

SPECIFICATIONS

Third drum (H3) (optional)

Max. line pull (1st layer)

69,915 lbf (311 kN)

Rated line pull (all layers)

29,760 lbf (132.4 kN)

590 mm P.C.D × 55,600 mm Lg., grooved for 26 mm dia.

wire rope. Rope capacity is 1,115 ft (340 m) storage length.

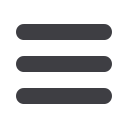

View towards the front of the machine : W1, H2 and H1 drums

Drums :

Powered by hydraulic variable displacement motors, driven through planetary reducers.

Negative brake

A spring-set, hydraulically released multiple disc brake

and a safety spooled load control counter - balance valve

are mounted on the hoist motor.

Drum lock

External ratchet for locking drum

Load hoist (H1 & H2) drums (Non-free fall)

Max. line pull (1st layer)

57,035 lbf (254 kN)

Rated line pull (all layers)

33,045 lbf (147 kN)

620 mm P.C.D × 926 mm Lg., grooved for 28 mm dia. wire

rope. Rope capacity is 1,969 ft (600 m) storage length.

Free fall function (optional)

Maximum line pull (1st layer)

61,640 lbf (274.2 kN)

Rated line pull (all layers)

33,045 lbf (147 kN)

Boom drum (W1)

Double drum, grooved for 26 mm wire rope.

Luffing jib drum (W2) (optional), mounted on the base

boom, grooved for 26 mm wire rope.

Steering mechanism :

The hydraulic propel system provides both skid steering and

counter-rotating steering.

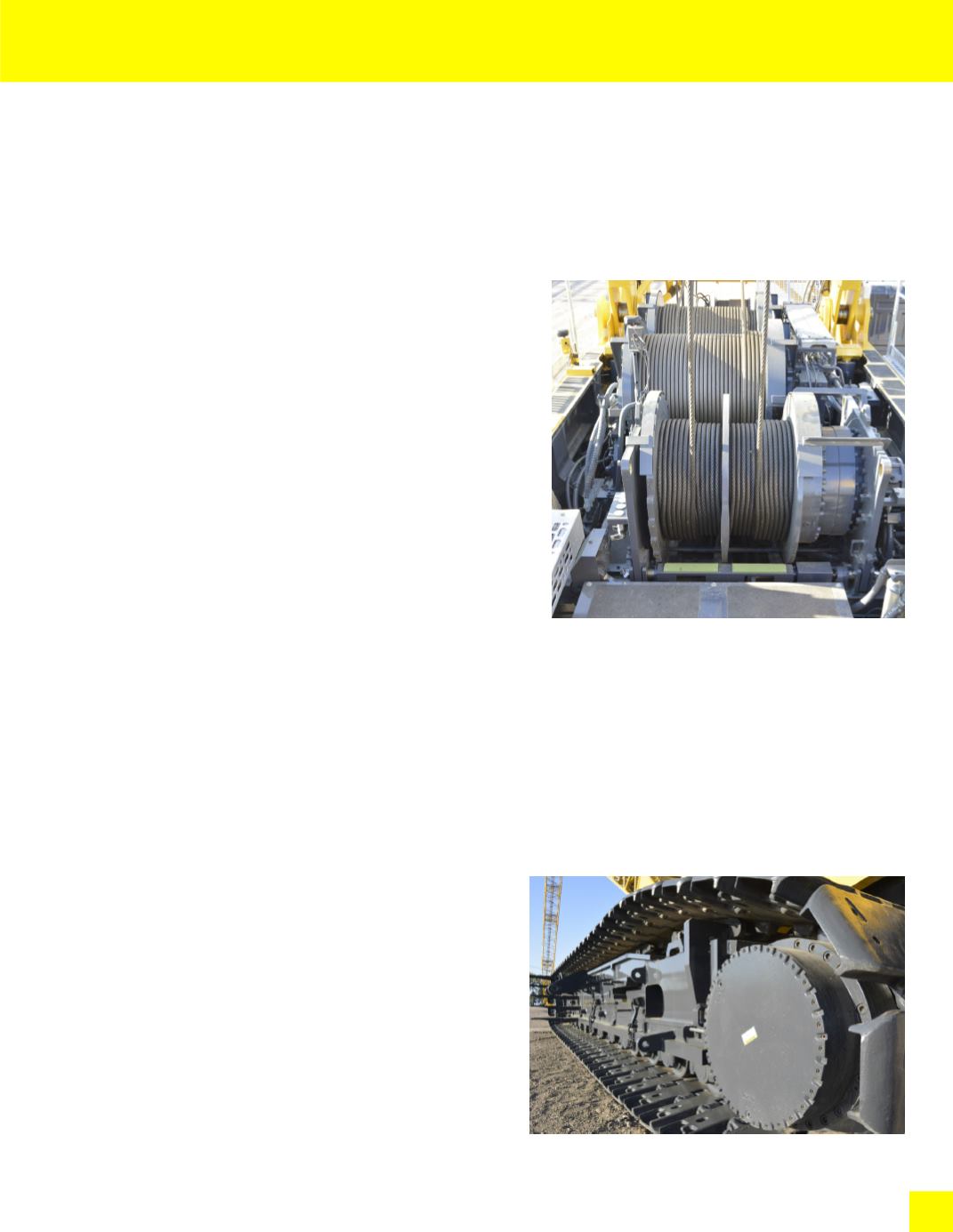

Crawler shoe :

Casted 52″ shoe is in standard.

(48″ shoe is optional)

Track rollers :

The track rollers are sealed for maintenance free operation.

Lower Machinery

Carbody frame :

High-tensile steel welded axle in constructed frame.

Translifters :

The function allows quick and easy crawler frame removal

and trailer loading. The swing arm and the remote-

controlled 4 vertical cylinders are all standard features.

Crawlers :

Crawler assemblies are designed with quick disconnects for

individual removal as a unit from axles.

Crawler belt tension adjusted by hydraulic jack and

maintained by shims between the drive unit block and frame.

Crawler drive :

Each crawler has double motors, one in front and one in the rear,

delivering steady, powerful traction for smooth on-site travel.

Each drive consists of a hydraulic motor driving a propel

tumbler through a planetary gear box. The hydraulic motor

and gear box are built into the crawler side frame.

Crawler brake :

Multiple disc type, spring set, hydraulically released parking

brakes are built into each propel drive.